In the food processing industry, efficiency and quality are paramount. One technology that has consistently proven its worth in achieving these goals is the tunnel freezer. Designed for high-volume freezing with exceptional speed and uniformity, tunnel freezers are a game-changer for businesses looking to enhance their production capabilities.

Let’s delve into the world of tunnel freezers and explore how they can transform your operations.

What is a tunnel freezer?

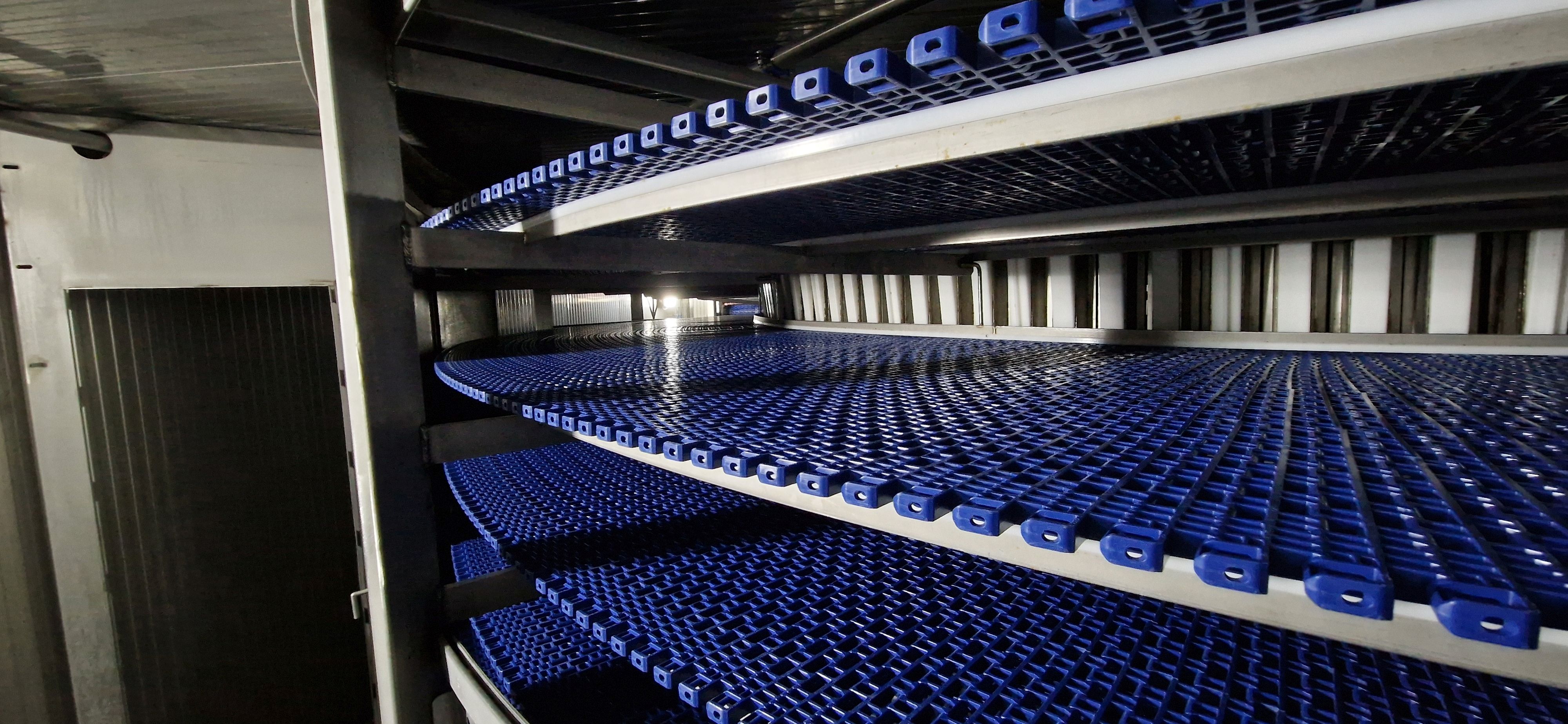

A tunnel freezer is a type of industrial freezer that uses a continuous conveyor system to transport products through a freezing tunnel. The tunnel is equipped with powerful fans and evaporators that rapidly lower the temperature, ensuring that products are quickly and evenly frozen. This method is ideal for high-volume operations, offering a streamlined and efficient solution for large-scale freezing needs.

The benefits of tunnel freezing

Tunnel freezers offer numerous advantages that make them a preferred choice for many food processing businesses. One of the primary benefits is the rapid freezing capability. By quickly reducing the temperature of products, tunnel freezers help preserve the texture, flavor, and nutritional value of food, which is crucial for maintaining high-quality standards.

Consistency is another significant advantage. Tunnel freezers ensure uniform freezing across all products, reducing the risk of uneven temperatures that can lead to spoilage or quality degradation. This consistency is vital for products that require precise freezing conditions, such as seafood, bakery items, and prepared meals.

Applications across various industries

Tunnel freezers are versatile and can be used in a wide range of industries. In the food processing sector, they are particularly popular for freezing fruits, vegetables, meats, and ready-to-eat meals. The pharmaceutical industry also benefits from tunnel freezers, using them to store temperature-sensitive products. Furthermore, these freezers are employed in industrial settings for freezing raw materials and intermediate goods, ensuring they remain in optimal condition during processing.

Enhancing productivity and efficiency

One of the standout features of tunnel freezers is their ability to enhance productivity. The continuous conveyor system allows for high throughput, making it possible to freeze large quantities of products in a short amount of time. This efficiency translates into higher production rates and the ability to meet increasing demand without compromising on quality.

Additionally, tunnel freezers are designed with energy efficiency in mind. Modern tunnel freezers incorporate advanced technology to minimize energy consumption while maximizing freezing power. This not only helps reduce operational costs but also supports sustainability efforts by lowering the environmental impact of freezing processes.

Customizable solutions for every need

Tunnel freezers are highly customizable, allowing businesses to tailor the equipment to their specific requirements. From the size of the freezer to the type of conveyor system, every aspect can be adjusted to optimize performance for different types of products and production lines. This flexibility ensures that businesses can invest in a freezing solution that perfectly aligns with their operational needs.

Future-proofing your freezing technology

As the demand for high-quality frozen products continues to rise, staying ahead of technological advancements is essential. Tunnel freezers represent the future of freezing technology, offering unparalleled speed, efficiency, and quality. By investing in a tunnel freezer, businesses can future-proof their operations, ensuring they remain competitive in a rapidly evolving market.

Partner with industrialfreezing.com for your tunnel freezer needs

If you’re ready to take your freezing capabilities to the next level, Industrialfreezing.com is your go-to source for state-of-the-art tunnel freezers. With a dedication to innovation and customer satisfaction, Industrialfreezing.com provides top-quality freezing solutions tailored to your specific needs. Their expertise in tunnel freezing technology ensures that you receive the best equipment to enhance your production processes and maintain product excellence.