In the realm of industrial manufacturing, the quest to streamline operations and minimize costs is perpetual. Labor expenses loom large on the balance sheets of organizations, necessitating strategic interventions.

Automation emerges as a pivotal tool in this endeavor, not merely replacing workers but enhancing their efficacy. Concurrently, modern scheduling software offers a data-driven approach to workforce management, optimizing staffing levels and curtailing overtime expenses.

By integrating these technologies seamlessly into their operations, manufacturers can achieve significant cost savings without compromising productivity or jeopardizing workplace safety.

For more information surrounding automation and how it relates to improved efficiency, please read on to the resource highlighted alongside this post.

In the realm of industrial manufacturing, the quest to streamline operations and minimize costs is perpetual. Labor expenses loom large on the balance sheets of organizations, necessitating strategic interventions.

Automation emerges as a pivotal tool in this endeavor, not merely replacing workers but enhancing their efficacy. Concurrently, modern scheduling software offers a data-driven approach to workforce management, optimizing staffing levels and curtailing overtime expenses.

By integrating these technologies seamlessly into their operations, manufacturers can achieve significant cost savings without compromising productivity or jeopardizing workplace safety.

For more information surrounding automation and how it relates to improved efficiency, please read on to the resource highlighted alongside this post.

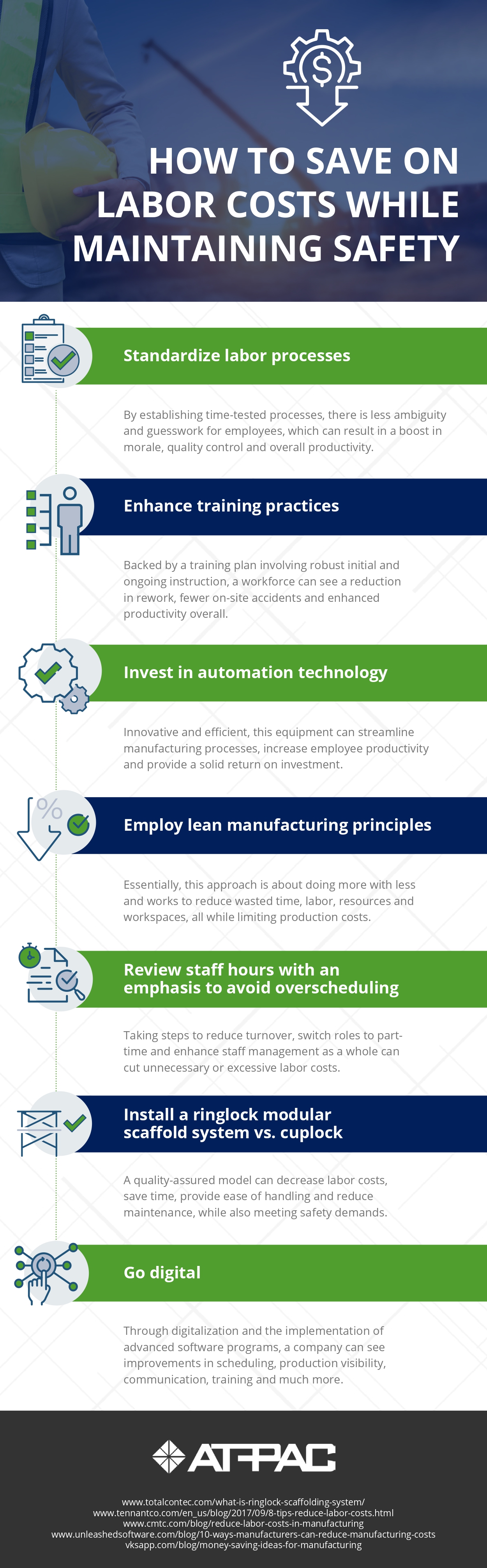

How To Save On Labor Costs While Maintaining Safety was provided by Atlantic Pacific Equipment, a scaffolding parts supplier