Downtime poses a major threat in manufacturing, draining resources and eroding trust with every halted production line. Beyond lost productivity, it jeopardizes vital customer relationships, as unmet commitments push clients toward competitors.

While some disruptions are unavoidable, many stem from preventable causes like neglected maintenance and insufficient training. Addressing these issues proactively is key to maintaining seamless operations.

By investing upfront in measures like preventive maintenance and robust data management, manufacturers can shield themselves from costly setbacks such as facility-wide downtime.

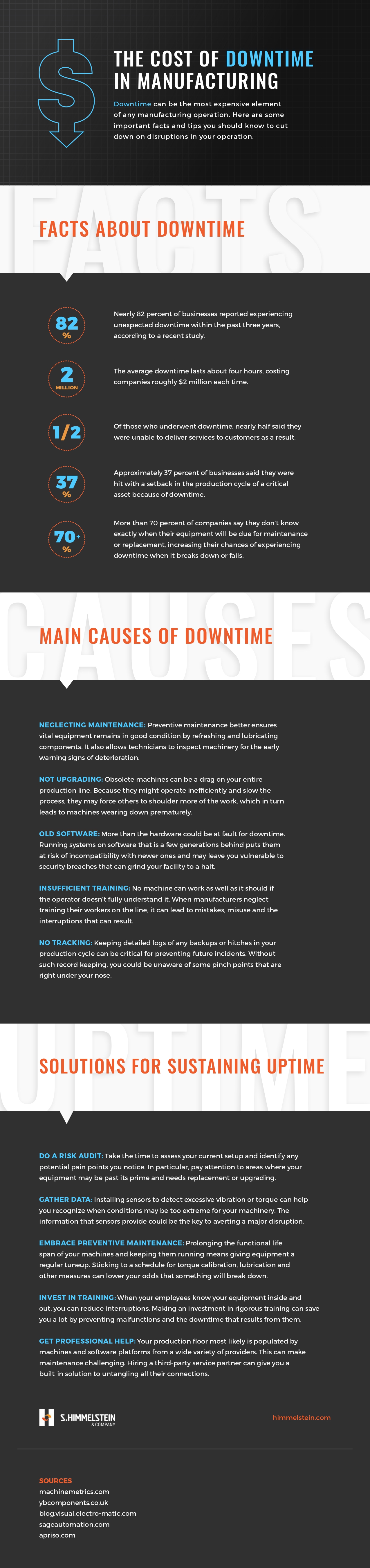

To learn more about the ways in which maintenance technologies are contributing to reduced downtime, continue reading on through the resource included alongside this post.

The Cost Of Downtime In Manufacturing, provided by S Himmelstein and Company, the organization to shop with for your next torque transducer