In the ever-evolving landscape of manufacturing, constant change is a prevailing force. Fortunately, manufacturers equipped to navigate these shifts are those who conscientiously stay abreast of industry trends and seamlessly integrate them into their operational frameworks. The advent of technological innovations has played a pivotal role in enabling manufacturers to not only weather difficult and uncertain times but also to thrive financially. One standout example of such technological progress is the pervasive integration of artificial intelligence (AI) within the manufacturing sector.

AI has emerged as a transformative force, ushering in efficiencies across various facets of manufacturing operations. A notable application lies in its ability to analyze data gathered by industrial sensors, swiftly detecting and effectively identifying potential problems. This technological marvel extends its prowess to addressing supply chain challenges by empowering manufacturers to pinpoint and rectify inefficiencies. By providing proactive insights, AI enables manufacturers to stay ahead of global scenarios that could potentially escalate costs, ranging from weather events to tariff conflicts.

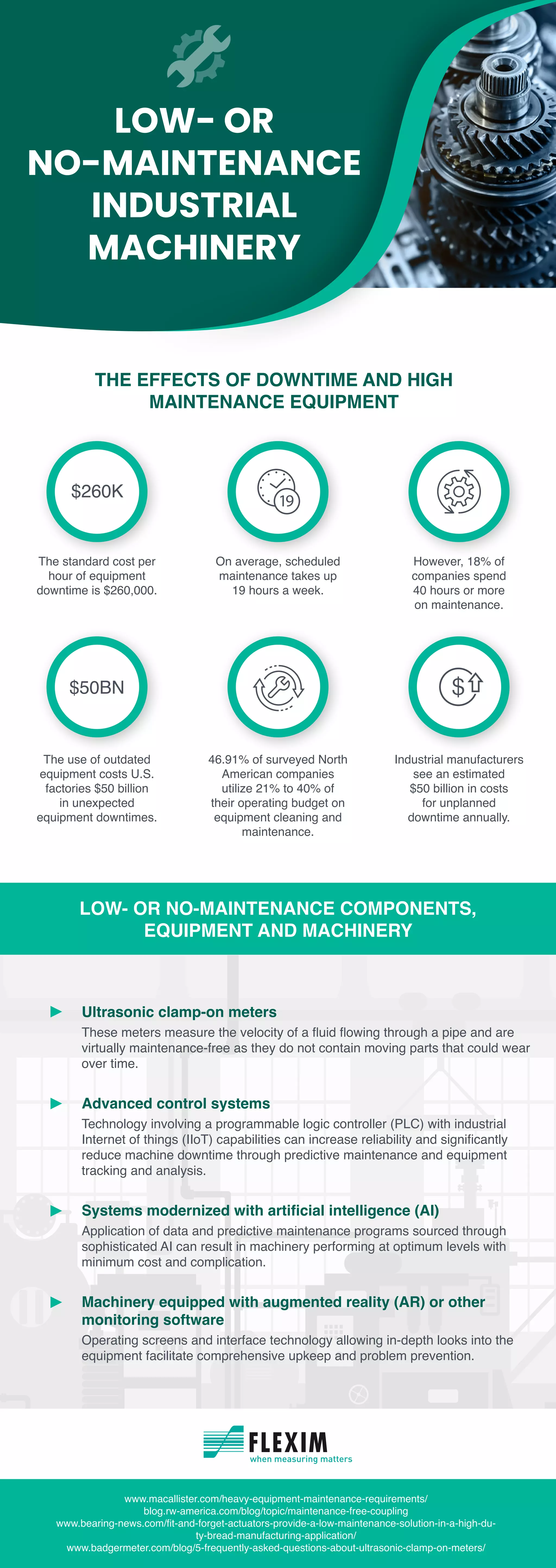

Contrary to the fantastical depictions often associated with science fiction, AI systems are integral components that underpin the success of predictive maintenance strategies. These systems facilitate the early identification of issues, ensuring timely intervention and maintenance.

For more information surrounding artificial intelligence and how it contributes to the efficacy of predictive maintenance, please read through the detailed insights provided within the resource supported alongside this post.

Low Or No Maintenance Industrial Machinery was provided by FLEXIM